Selecting and implementing new distillery management software is a huge step forward for your business and the beginning of a digital and operational transformation. Enterprise resource planning (ERP) systems solve many important operational issues, but they don’t do it in a vacuum. In order to achieve maximum ROI, you and your colleagues need to first take advantage of industry best practices and processes, and second, know how to use the system effectively.

Implementing industry best practices will help you optimize your workflows, streamline your inventory management and track your production processes, while well-structured software training will get your staff aligned and informed. Keep reading to find out more about getting the most out of your distillery management software.

Optimizing workflows and processes

One key benefit of distillery management software is the ability to optimize and streamline workflows and processes. By automating tasks and using the software to track and manage your inventory and production processes, you can save time, reduce errors and increase efficiency.

Automating tasks

The ability to automate time-consuming and repetitive tasks is one of the biggest benefits of distillery management software. Automation saves time and reduces the risk of errors, freeing up your team to focus on more important tasks. (Like creating great spirits!)

There are a variety of tasks that can be automated with distillery management software. For example, you can use the software to automate your inventory management processes, such as tracking stock levels and setting up automatic reorder points. This ensures that you always have the ingredients and supplies you need on hand, without having to manually track and manage inventory.

You can also use the software to automate your production processes, such as scheduling and tracking batch production. This allows you to easily manage your production schedule and ensure that your team is always working on the right tasks at the right time. Additionally, you can use the software to automate data entry tasks, such as recording production data, which reduces the risk of errors and saves time.

Automating processes within software can significantly improve your operational efficiency and reduce costs. This allows you and your team to focus on more important tasks – such as product development and innovation – while still maintaining a high level of productivity and accuracy in your day-to-day operations.

Streamlining inventory management

Inventory management is a critical aspect of any distillery operation. Keeping track of the raw materials, supplies and finished products that are used and produced by the distillery is fundamental. Without effective inventory management, it can be difficult to know what resources are available, what needs to be ordered and when products are ready for sale.

Distillery ERP systems can streamline inventory management processes and make them more efficient. It can help track inventory levels in real time, alerting operators when supplies are running low and ensuring that production doesn’t come to a halt. It can also help optimize inventory levels by providing data on consumption rates and forecasting demand. With this information, operators can make informed decisions about when to order new supplies.

Another way distillery management software can help streamline inventory management is by providing a centralized location for tracking inventory. With all inventory data stored in one place, operators can quickly and easily access information on what supplies are available, where they are located and when they were last used.

Optimizing production processes

Production processes like recipe management, ingredient tracking and packaging can be optimized with distillery management software. Distilleries can create and manage recipes for their products in one centralized location. It’s easier to track ingredients and production processes, ensuring that each batch of product is consistent in taste and quality. Additionally, recipe management can help to identify potential areas for improvement in the production process, leading to better efficiency and cost savings.

Another important aspect of production management is ingredient tracking. With distillery management software, distilleries can easily track inventory levels of raw materials and finished products. This helps to avoid stockouts or overstocking, which can cause delays and waste. Distillery management software can also provide real-time visibility into ingredient usage during the production process, making it easier to identify any issues or inefficiencies.

Distillery management software can also help to streamline packaging processes. By tracking inventory levels of packaging materials such as bottles, labels and caps, distilleries can ensure that packaging is always available when needed.

All Aboard the Software Change Train

Once you have chosen the most appropriate distillery management software for your business and optimized your workflows and processes, the next step is to ensure that your employees are fully trained in using the software – and on board with all process changes – so your organization gains the most value from the investment.

Depending on the size of your distillery, different employees, teams, departments or locations will be responsible for different aspects of the production process. Your production team, for example, will need to know how to use the software to track ingredients and recipes, while your logistics team will need to know how to use the software to manage shipping and delivery schedules. Training your employees to use the software effectively is critical to maximizing the ROI of your distillery management software. Without proper training, your employees may not use the software to its full potential, which can lead to lost time and decreased efficiency.

A best practice is to utilize in-person or on-demand training resources from your implementation partner or software provider. First train team leads and any subject matter experts (SMEs) who can be champions of change, and who can then help train and support other employees who will be using the software. This is what’s called a “train the trainer” approach.

The Importance of Change Management

Creating a culture of learning and continuous improvement within your distillery will be critical to your digital transformation. Consider implementing a change management plan that will inspire your team to embrace the new system and processes. Encourage your employees to ask questions and offer suggestions for how the software can be used more effectively. This can help identify areas for improvement and further streamline your operations.

Consulting services and training can be invaluable when it comes to ensuring your employees are getting the most value out of your distillery management software platform. While the software itself may be easy to use, it can still take some time for your team to get used to working with it and fully understand how to leverage its features and capabilities.

One option is to bring in a consultant who specializes in distillery management software to provide guidance and training to your team. This person can work with your employees one-on-one or in a group setting to help them understand how to use the software to its full potential. They can also provide insights into additional best practices for managing your distillery and optimizing your processes, based on their industry experience and expertise.

Training is another important aspect to consider. As mentioned above, many distillery management software providers offer training programs as part of their service package. These programs can be tailored to your specific needs and provide your team with the tools and knowledge they need to get the most out of the software. This training can be done remotely or in-person, depending on your preference and budget.

By investing in employee training and creating a culture of change and continuous improvement, you can ensure that your distillery management software is being used to its full potential, leading to greater operational efficiency, cost savings and increased profitability.

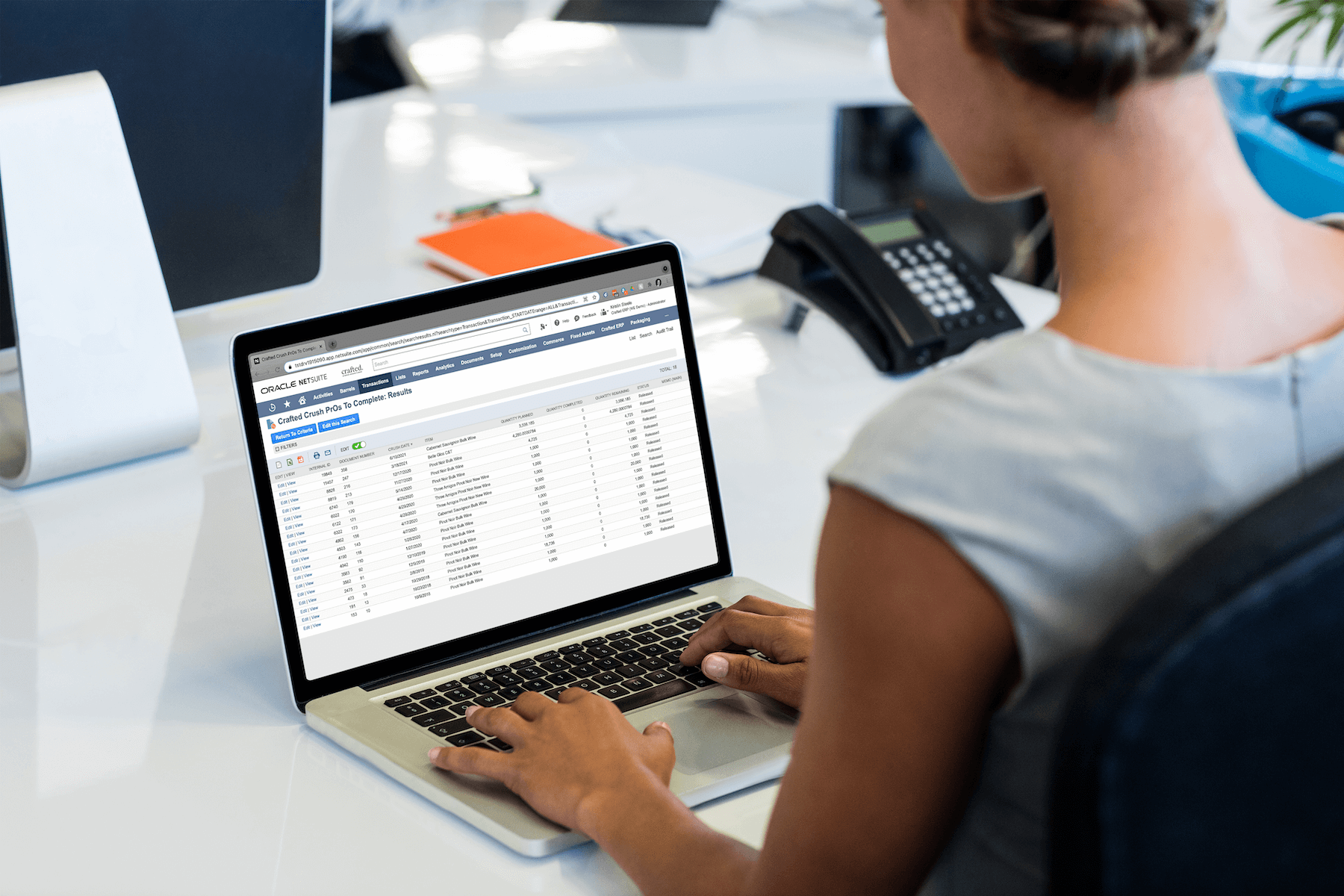

Crafted ERP Distillery Management Software

Distillery management software might be one of the most important tools to position your business for exponential growth. By implementing industry best practices and optimizing your processes, you can ensure that you are getting the most out of your investment.

Training employees and inspiring them to embrace your new system will also help you achieve maximum ROI. The better your team understands new processes and the more efficiently they use the software, the faster you hit your goals.

Crafted ERP can help your distillery grow as big as you can imagine it. Contact us today to learn more about our distillery management software.