Alcoholic beverage supply chains are complex networks of processes that start with raw materials and end with a finished product. For craft distilleries, these processes can be a minefield of potential disasters, where a single misstep can lead to costly delays or, worse, product loss. This is where distillery management software is crucial. It offers a way to streamline operations, manage risk and maintain the delicate balance of supply and demand.

The Anatomy of a Distillery Supply Chain

A distillery’s supply chain is a complex, interconnected web that stretches from the procurement of raw materials to the delivery of finished products to retailers. This network is filled with intricacies, where a minor disruption at any point can ripple through the entire system, potentially causing significant losses. To fully understand how the right distillery management software can help navigate this labyrinth, it’s important to first dissect the supply chain’s anatomy.

Procurement of Distillery Ingredients

The distillery supply chain begins with the procurement of raw materials. This includes grains (such as barley, corn, rye or wheat), yeast, water and, in some cases, fruits and other flavoring agents. Sourcing these ingredients involves establishing and maintaining relationships with reliable suppliers, negotiating contracts and ensuring timely deliveries.

However, procurement is also susceptible to various risks. Crop failures, price fluctuations or logistical issues can cause ingredient shortages. Additionally, the quality of the ingredients can significantly affect the end product, emphasizing the need for stringent quality control measures.

Production Process

Once the ingredients have been sourced, they enter the production process, which consists of several stages: mashing, fermentation, distillation and maturation. Each of these stages requires careful monitoring and control. For example, temperature and pH need to be precisely managed during fermentation, and the distillation process requires accurate control of heat and pressure.

Errors or inconsistencies at any stage of production can lead to significant quality issues, and in severe cases, may require entire batches to be discarded. Moreover, each stage has its own timeline, and delays can have a cascading effect on the overall production schedule.

Bottling and Packaging

After maturation, the spirits are ready for bottling and packaging. This stage involves additional supply chain elements, such as sourcing bottles, corks, labels and packaging materials. These elements must be coordinated with the production process to ensure that the finished spirits can be bottled and packaged without delay.

Distribution and Sales

Once bottled and packaged, the products are distributed to wholesalers, retailers or directly to consumers. This step involves transportation logistics, inventory management at various locations, and maintaining relationships with a network of distributors and retailers.

Furthermore, this stage of the supply chain is also subject to legal and regulatory constraints. For instance, different regions have different laws regarding the sale and distribution of alcoholic beverages, which distilleries must comply with to avoid legal penalties.

Customer Service and Support

Finally, the supply chain doesn’t end when the product reaches the retailer or consumer. Post-sale services, such as customer support, returns management and feedback collection, are also part of the supply chain. These services impact customer satisfaction and loyalty, which in turn influence future sales and the distillery’s reputation.

The Role of Distillery ERP Software

ERP (enterprise resource planning) software can integrate all aspects of a business into one comprehensive system. This includes procurement, production, inventory management, sales, accounting and more.

An ERP solution built specifically for the craft spirits industry can help manage the complexities of their unique supply chain. It allows for real-time monitoring of inventory, from raw materials to finished products, and can automatically reorder supplies when they’re low. This ensures you always have the right spirits-making ingredients when you need them.

Additionally, distillery ERP software can track the batch process, allowing for quick identification and isolation of any issues. It also provides critical data that can be used to optimize production, reducing waste and improving efficiency.

How a Distillery ERP Can Improve Compliance

For the alcoholic beverage industry, compliance with regulations is not just a best practice; it’s a legal requirement. Distilleries are often subject to a multitude of laws and regulations, ranging from local health codes to international export rules. Navigating this legal labyrinth can be a daunting task, and non-compliance can lead to severe penalties, including fines and even business closure. This is where a distillery ERP becomes invaluable, offering tools and features that can simplify and streamline compliance management.

Real-time Data Tracking

Compliance often requires keeping accurate records of various business operations. For instance, you might need to document your ingredient sources, track your production volumes, and record your waste disposal methods. With a distillery ERP, you can automate these data tracking processes, ensuring you always have the up-to-date records you need for regulatory reporting.

Centralized Compliance Management

An ERP built for distilleries can centralize all compliance-related activities in one system. This means that instead of juggling multiple platforms for different compliance tasks, you can manage everything from a single dashboard. This centralized approach not only makes compliance management more efficient but also reduces the risk of errors that could lead to non-compliance.

Automated Regulatory Reporting

Reporting is a critical part of compliance. Regulators may require regular reports on various aspects of your operations, such as production volumes, ingredient usage and safety incidents. Manual reporting can be time-consuming and prone to errors. However, a distillery ERP can automate this process, generating accurate reports at the click of a button.

Traceability and Auditability

Traceability is crucial when it comes to ingredient sourcing and product recall scenarios. When thinking about detailed ingredient tracking, Aaron Selya, head distiller of Philadelphia Distilling, told us:

“We have very limited options and very tight restrictions on which lots of botanicals we’re getting in and whether or not they fit the flavor profile that we’re looking for. Crafted ERP allows us to track back to which lots of botanicals went into a specific bottle.”

A distillery ERP can provide detailed traceability records, showing the journey of every ingredient from supplier to final product. This not only aids in recall scenarios but also helps in verifying the authenticity and quality of ingredients.

Auditability is also a key feature of a distillery ERP. The system can provide a complete audit trail, documenting every action taken within the system. This transparency is invaluable during audits, as it helps demonstrate your commitment to compliance and allows you to quickly address any issues raised by auditors.

The Benefits of Crafted ERP for Distilleries

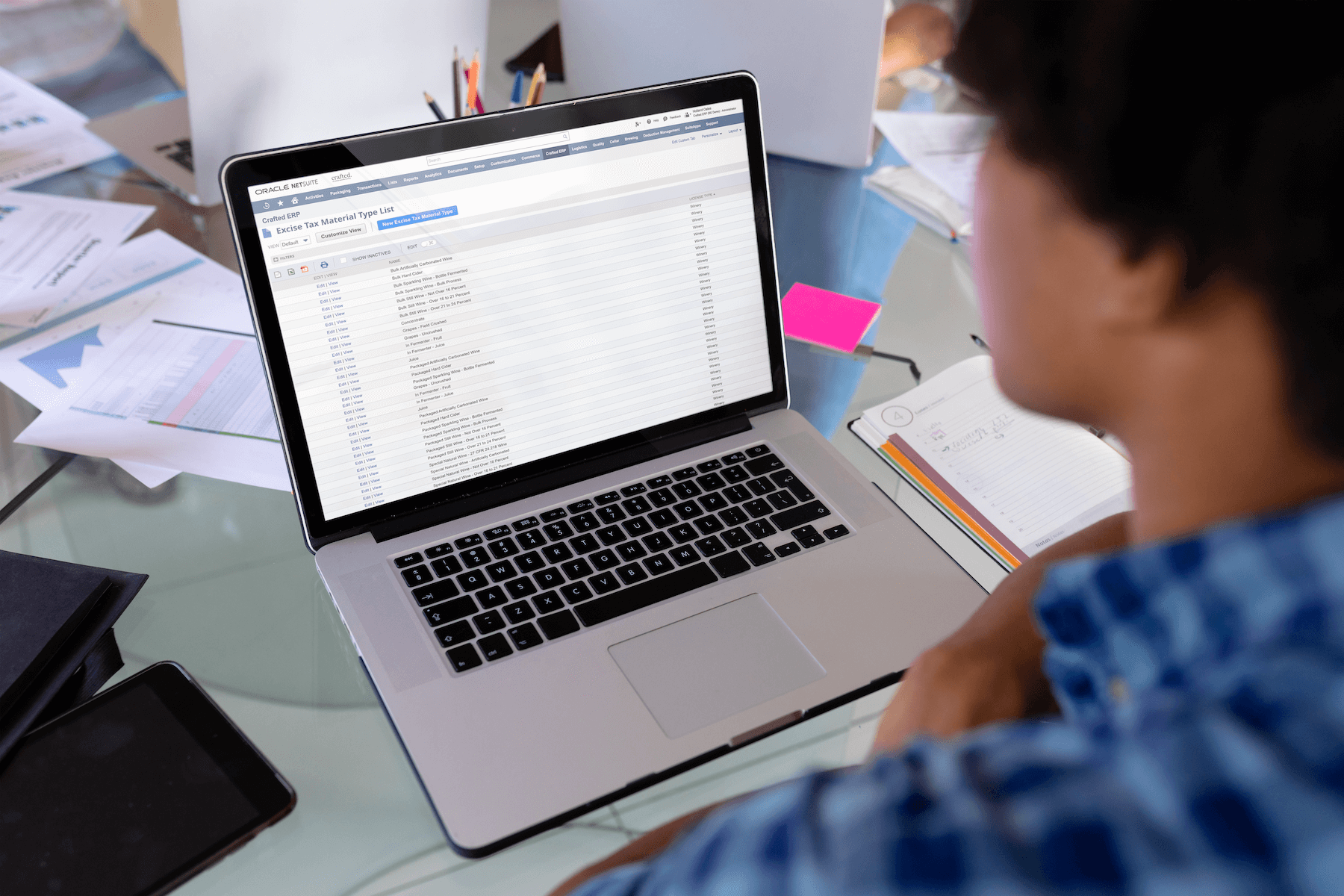

It’s also worth mentioning how a specific platform like Crafted ERP could benefit distilleries. With its focus on the alcoholic beverage industry, it provides solutions tailored to the unique challenges distilleries face.

Crafted ERP offers real-time inventory data from distillery ingredients to finished products. It can also help you manage your relationships with suppliers and track your products’ journey from distillery to retailer. Moreover, it provides tools to optimize production and reduce waste, ultimately improving your bottom line.

Distillery Management Software for Supply Chain

Managing a distillery’s supply chain can be a complex task, fraught with potential disasters. However, a distillery ERP can help you navigate these challenges with ease. It can:

- Provide real-time monitoring of your supply chain, from procurement of distillery ingredients to the sale of finished products, helping you identify and address issues before they escalate.

- Offer predictive analytics that can foresee potential supply chain disruptions, allowing you to take preventative action.

- Streamline your operations by integrating all aspects of your business into one comprehensive system.

- Help you balance supply and demand, ensuring you always have the right distillery ingredients when you need them.

- Improve your relationships with suppliers and customers by providing a clear and transparent view of your supply chain.

In the unpredictable world of the craft spirits industry, a distillery ERP isn’t just a nice-to-have — it’s a necessity. By adopting a comprehensive distillery management software like Crafted ERP, you can ensure a smoother, more efficient operation and turn potential supply chain disasters into opportunities for growth and improvement.

The right tools and systems are essential to navigate the complex landscapes of supply chains effectively. They not only help in avoiding disasters but also in leveraging opportunities, fostering growth and driving innovation in your distillery business. Ultimately, the smart use of technology can lead to better products, happier customers and a stronger bottom line. Ready to take the next step? Reach out to our team of experienced bev alc professionals today.