“What do you mean our software is slowing us down?” You have the recipes, the demand and a dedicated team — but when scaling up, your tech stack is as tangled as a forgotten extension cord in the garage. Sound familiar?

Suppose your brewery, distillery or brewstillery, like many, is juggling multiple software systems. In that case, you’re probably spending more time fighting with spreadsheets and manual processes than focusing on making great beverages, cutting costs, and growing your business.

You’re not alone. Our newest industry survey of senior brewery and distillery management reveals a clear trend: the more disconnected software tools you use, the harder it is to scale. Businesses with four or more systems report automation gaps, lost time and frustration. Companies running six or more platforms are drowning in redundancy, manual reconciliation and errors.

So, what’s the solution? There’s no surprise here: industry-specific ERP software that connects your inventory, production, compliance and financial tracking in a single platform. With this upgrade, breweries and distilleries can move from operational headaches to smooth, scalable growth.

More Software, More Problems

There was a time when using separate tools for inventory, production and finance made sense. You picked the best tool for each job, and everything worked — kind of. But fast forward to today, and you’re likely dealing with a Frankenstein-ed system that’s less a sum of all its parts than a constant source of inefficiency and frustration.

What our survey found:

- Breweries and distilleries using four or more software tools report major automation struggles and lack of real-time visibility.

- Companies with six or more disconnected systems rely too heavily on spreadsheets, slowing decision-making.

- Most respondents strongly believe a single, unified system will eliminate inefficiencies.

The bottom line? Your software should make your life easier, your business more profitable, and your pathways to growth more attainable. If it’s not, it’s time for a change.

Why Disconnected Systems Are Holding You Back

- Data silos and conflicting reports: Every department is working in its own system — inventory in one, production schedules in another, sales elsewhere, and financials in yet another. Without integration, your team spends hours manually reconciling data, and decision-making turns into guesswork.

- Manual workarounds create more errors: When systems don’t talk to each other, employees rely on spreadsheets, emails and handwritten notes, which means:

- Typos and miscounts lead to compliance mistakes and financial inaccuracies

- Production bottlenecks arise from outdated scheduling info

- Longer processing times slow down even basic tasks

- No real-time operational visibility means slower decision-making: Imagine needing to adjust inventory levels but finding out three days too late. Disconnected systems leave you reacting instead of planning. Without real-time insights, you can’t optimize stock, anticipate demand or adjust pricing strategies.

- IT costs are rising and unnecessary: Running multiple software systems isn’t just inefficient — it’s expensive:

- Multiple software subscriptions add up fast

- Integration and IT maintenance costs drain resources

- Training employees on several platforms slows down productivity

The fix? Industry-specific ERP brings everything into one system so you can stabilize, streamline and succeed.

Hamstrung by the Tech Stack

Today’s beverage industry changes at breakneck speed. The popularity of hard seltzers, RTD cocktails, and no- or low-alcohol (NOLO) beverages is a trend that has emerged faster than you could say “limited release.”

But here’s the catch: expanding into new product lines isn’t just adding ingredients. It’s about managing a more complex supply chain, tighter inventory tracking, and new compliance requirements. Most outdated tech stacks simply aren’t built for that. Instead, they’re cobbled together based on how you are doing things, not how you want to or should be doing things.

Survey Says: Tech Roadblocks Are Limiting Growth

- Businesses using four or more software systems lack the integrated inventory and forecasting tools for confident expansion.

- Companies with fewer than three systems report lower frustration and greater success launching new product lines.

- Respondents who rate their software effectiveness as 7 out of 10 or higher are significantly more confident in pursuing a product diversification strategy.

Three Ways an Inefficient Tech Stack Can Ruin Your Plans

- Disconnected systems struggle with multi-ingredient recipes: Expanding into RTD cocktails or flavored malt beverages? You now need to track:

- Multiple base spirits (vodka, gin, whiskey)

- Flavored ingredients (juices, botanicals, extracts)

- Packaging materials (bottles, cans, labels, caps)

- Sweeteners, carbonation, stabilizers

- Customer-owned inventory (if you’re co-packing)

- Lack of real-time data makes scaling a guessing game: Without accurate demand forecasting, you risk:

- Overproduction (wasted inventory, higher carrying costs, tied-up cash flow)

- Underproduction (lost sales, frustrated customers, stockouts, strained supplier relationships)

- Poor financial planning based on inaccurate forecasting

- Cost tracking is a disaster without the right system: Expanding into a new product line only works if it’s profitable, but many breweries and distilleries don’t have real-time cost tracking. What happens when you price a new RTD cocktail too low, only to realize months later that it’s costing you money?

- Hidden expenses eat into your margins

- Pricing inconsistencies drive customers away

- Cash flow struggles limit future investment

The fix? An industry-specific ERP solution with built-in inventory tracking, cost forecasting, and production scheduling that allows you to stabilize, scale, and go to market confidently.

Check Yourself Before the Fines Hit Your Shelf

There’s no way around it — breweries and distilleries operate in one of the most heavily regulated industries in the country. If your tax and compliance processes are a headache, your software isn’t doing its job.

Survey Insights on Compliance Challenges

- Tax reporting and compliance tracking are among the biggest pain points

- Manual tax filing leads to reporting errors, penalties and costly audits

- Many businesses lack an integrated system for tracking excise tax, ingredient sourcing and regulatory requirements

The Compliance Risks of an Outdated System

- Missed filing deadlines mean hefty penalties

- Manual data entry increases the risk of errors

- Poor cost tracking creates cash flow uncertainty

The fix? An industry-specific ERP system that equips you with automated compliance tracking tools so you never miss a deadline or an opportunity to save money.

Stuck in the Middle With Growing Pains

You’re at the sweet spot for growth but also at the most dangerous stage for making costly mistakes. At this crossroads, you’re dealing with:

- Expanding production volumes and new distribution channels

- Higher operating expenses that require tighter cost control

- More complex pricing structures across multiple product lines

Despite this, many emerging breweries and distilleries still rely on disconnected spreadsheets and outdated accounting systems, making financial tracking an absolute nightmare.

Where Beverage Companies Struggle the Most

- Inaccurate cost tracking = bad pricing decisions:

- Accurate pricing hinges on understanding true production costs

- Underpricing kills profits and overpricing kills sales

- Cash flow gets tied up in inventory mismanagement

- Cash flow problems that stall growth:

- Surprise shortages can halt production

- Expansion projects get delayed because financial forecasting is unreliable

- Securing financing becomes difficult and costly with unclear or poorly organized financial reporting

- No real-time profitability analysis:

- Are you selling enough high-margin products, or are low-margin ones dragging you down?

- Hidden costs could be eating into profits without you realizing it

- Scaling the wrong product line can set you back instead of pushing you forward

The fix? Industry-specific ERP that tracks costs, profitability and cash flow in real time so you can expand confidently instead of rolling the dice.

Industry-Specific ERP is the Ultimate Growth Hack

Without centralized beverage ERP software, businesses grapple with multiple logins, scattered reports and a lack of financial clarity. Survey insights reinforce this: beverage companies juggling multiple software tools experience the highest frustration levels, compliance risks and financial uncertainty.

What the data says about fixing these problems:

- Simplify your tech stack if you want to expand product lines.

- If you’re using 4+ systems, assess your inefficiencies.

- A single, industry-specific ERP solution reduces operational friction and boosts agility.

- Less tech complexity = more room for growth.

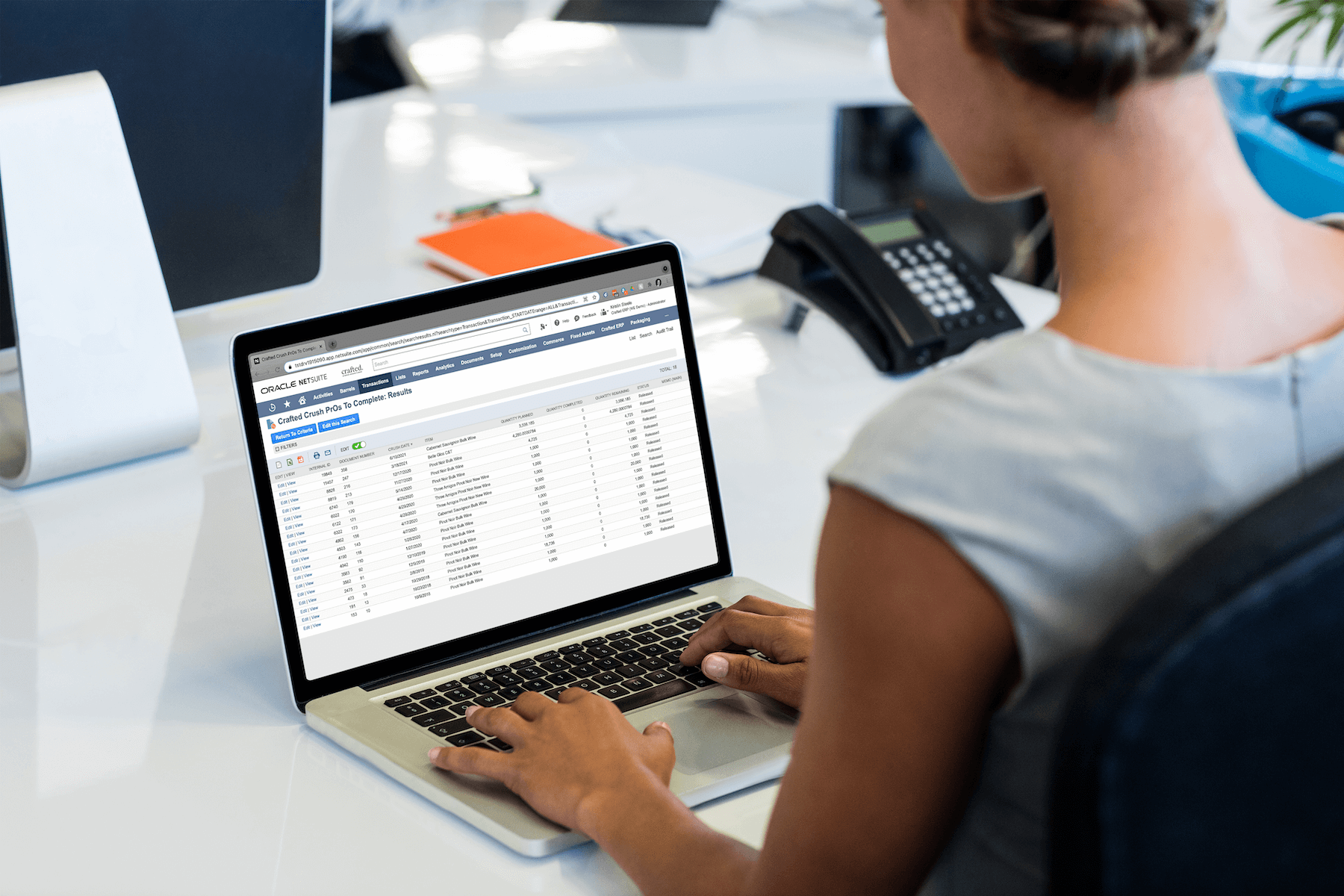

Crafted ERP is Built for Breweries & Distilleries

Generic ERP solutions try to do everything but can’t meet the specific needs of certain industries. Some of them claim to be an ERP but are not (hint: if you’re integrated with a different financial system, it’s not ERP). On the other hand, Crafted ERP is an actual industry-specific ERP system – built in the number one cloud ERP system, in fact – explicitly designed for craft beverage producers.

What Sets Crafted Apart?

First and foremost, Crafted offers unified, multi-license production and compliance. No other system on the market has the breadth and depth to support your beverage business wherever you want to take it. Additionally, you’ll enjoy the following:

- Batch and recipe management: Track multi-ingredient recipes with precision.

- Automated tax and compliance reporting: Stop worrying about TTB reporting, audits or fines.

- Integrated inventory, sales and financials: One system, total visibility across all beverage types.

Ditch Siloed Systems & Scale Smarter With Industry-Specific ERP

Growth shouldn’t mean more complexity, more spreadsheets or more headaches. With the right ERP, breweries and distilleries can streamline operations, boost profitability and scale their businesses.

Tired of disconnected systems? Let’s chat about how Crafted can simplify your operations and set you up for success.

Dive Into More Insights

Access a free copy of our white paper to learn more about how beverage producers like you struggle to scale and diversify operations due to a complicated tech stack.