Compliance doesn’t sleep. While your team scrambles to compile TTB reports from scattered spreadsheets, racing against filing deadlines, and praying the numbers match, your competitors are focusing on growth. The difference between them and you? They’ve turned mandatory compliance from a recurring nightmare into a routine automated process.

Here’s what compliance chaos actually looks like: Your operations manager spends the last week of every month hunting down production data across three different systems. The federal excise tax report requires manual transcription from tank logs into government templates. Your COLA applications sit in email threads while formulation changes get lost between R&D and final approvals. State reporting multiplies the chaos — different locations, different requirements, different deadlines, different formats. Meanwhile, an audit notice sits on someone’s desk, triggering a three-alarm fire drill to gather two years of scattered records.

The real damage extends beyond the obvious time drain. Every manual handoff introduces the potential for error, and in bev-alc, errors carry consequences. A miscalculation in excise tax reporting could cost you thousands of dollars in penalties. State filing errors risk license suspensions. Incorrect production records during an audit can spiral into months of legal remediation. Your team knows this, so they check, double-check and triple-check — burning valuable hours on verification that automated systems would eliminate.

What Manual Compliance May Be Costing You

Let’s explore a hypothetical example of a manual compliance process. A typical beverage operation dedicates 1-2 full-time employees to compliance tasks to gather data, prepare reports, manage submissions and maintain essential records. At $60,000-$80,000 per employee, that’s $120,000-$160,000 in direct labor.

But that’s just salary. Add the opportunity cost of your operations manager spending 20+ hours a month on report compilation, your CFO losing days for audit prep, and your production team halting work for physical inventory counts.

The penalty risk amplifies the cost. Federal excise tax errors can result in penalties ranging from tens to hundreds of thousands of dollars, depending on their severity. State violations can result in additional fines on top of that.

License suspensions — even temporary ones — can cost you thousands in lost sales. Then there’s the soft cost of reputation damage when compliance issues become public, affecting distributor relationships and consumer trust.

Compliance Automation Opportunities That Deliver Returns

You don’t have to relive the regulatory nightmare forever. Modern beverage ERP transforms compliance from reactive scrambling to proactive management. Here’s where compliance ROI materializes:

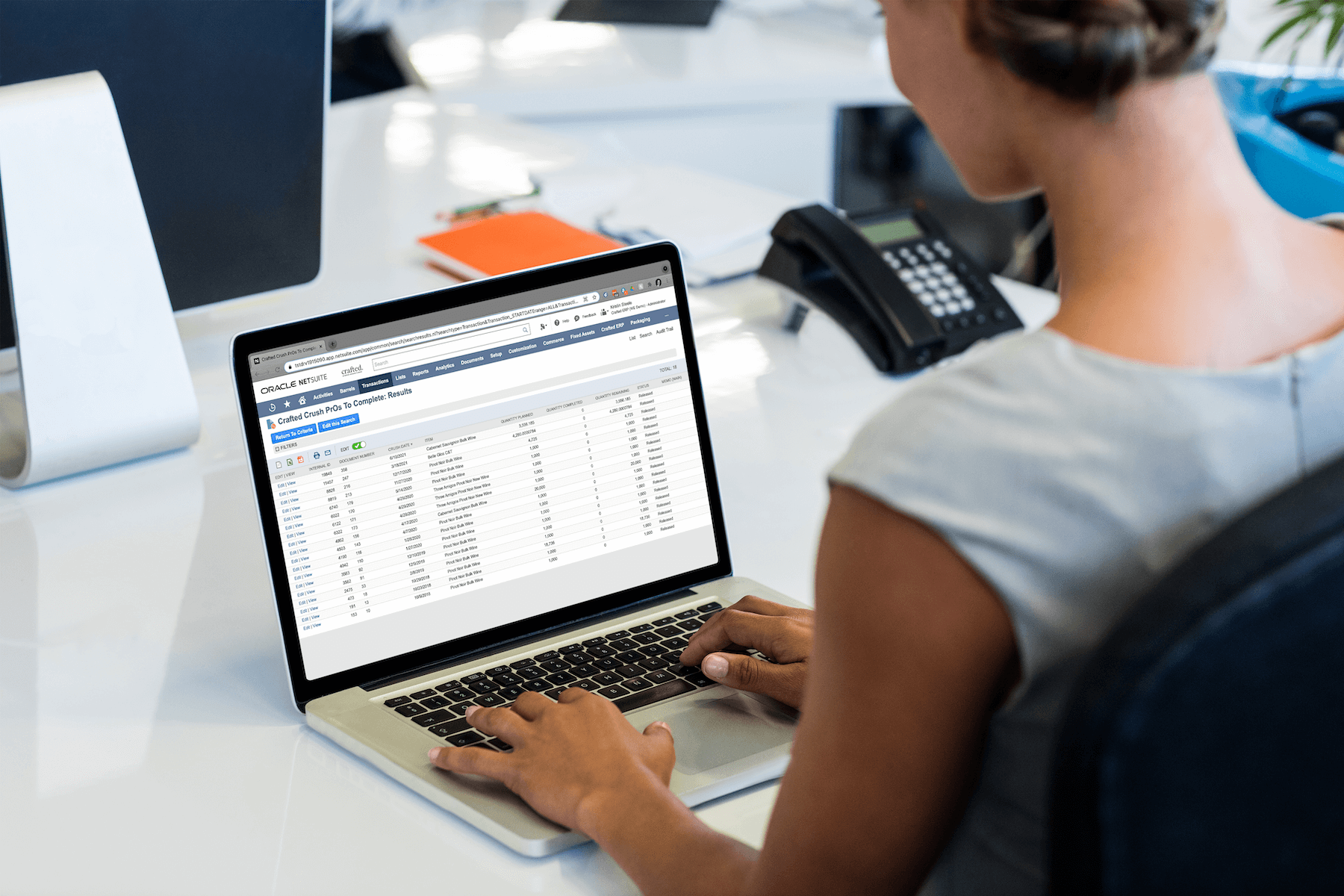

- Automated regulatory reporting: TTB reports, excise tax filings and state compliance documents are generated automatically in regulator-ready formats. No more transcription, manual calculations or formatting struggles.

- Label and license management: All COLA applications, formula approvals and license renewals live within the system with automated expiration alerts. Instead of discovering an expired license during a distributor audit, you’re notified 90 days in advance. Label changes are tracked through approval workflows, ensuring nothing ships without proper authorization.

- Audit trail maintenance: Every transaction, adjustment and approval is automatically logged with timestamps and user accountability. When auditors request three years of production records for a specific SKU, you deliver it in minutes, not weeks.

- Multi-state compliance orchestration: Different states require different rules, but a single system manages them all. The ERP tracks which products are approved where, calculates state-specific taxes, and generates jurisdiction-appropriate reports.

Building Compliance ROI That Sticks

Successful compliance automation requires more than software — it demands process standardization and cultural shift. Start with a compliance audit: map every report, document every requirement, and calculate the true time cost of current processes. This baseline becomes your ROI scorecard, identifying the highest-value automation targets.

Start with federal requirements — they’re uniform, well-defined and affect everyone. TTB reporting and federal excise tax offer quick wins that demonstrate value. Once the team sees monthly federal filings reduced from days to hours, expanding to state compliance meets less resistance.

Create clear workflow ownership. Assign responsibility for data accuracy at the source — production owns tank measurements, warehouse owns inventory counts, and finance owns pricing. When everyone knows their role in maintaining compliance-ready data, the system becomes self-reinforcing.

Build compliance checks into daily operations rather than treating them as monthly fire drills. Set up system validations that prevent non-compliant transactions, and establish exception reporting to flag anomalies before they become violations. Make audit-readiness a byproduct of normal operations, not a special project.

Measuring Success: Compliance Metrics That Matter

Compliance ROI is realized through both cost avoidance and efficiency gains. The obvious wins are measurable: hours spent on report preparation drop, audit preparation time is cut in half, and violation frequency approaches near zero. The financial impact is equally clear as you avoid costly penalties, eliminate legal fees, and maintain business continuity.

Strategic indicators reveal an even deeper transformation. Audit findings decrease as inspectors review organized, complete records. License renewals process on time, every time. Compliance is suddenly a growth enabler, not a bottleneck.

The most successful software adoptions result in increased compliance and labor efficiency, while also improving accuracy and completeness. Teams that once lived in fear of audits now welcome them as opportunities to demonstrate operational excellence. The compliance function shifts from defensive record-keeping to proactive risk management.

The Competitive Power of Compliance Excellence

In the bev-alc industry, compliance excellence isn’t just about avoiding penalties — it’s about enabling growth. When compliance is automated and reliable, you enter new states confidently and launch new products faster.

Consider the strategic advantages: You handle audits with easy-to-access documentation while competitors scramble to compile records. You expand distribution with the confidence that every license is current and every approval is documented. You negotiate with investors from a position of strength, demonstrating the operational maturity they require.

The businesses winning in bev-alc today aren’t necessarily the ones with the best liquid in the bottle. They’re the ones who’ve turned operational excellence into competitive advantage. Compliance is mandatory work, but doing it manually is optional — and increasingly untenable.

Modern beverage ERP doesn’t just manage compliance; it transforms it from a cost center to a strategic capability. It’s the difference between playing defense and playing to win.

Ready to go on offense? Let’s chat.