The craft beer market has experienced seismic shifts over the last several years. The rise of RTDs, FMBs and infused beverages has captivated consumers, along with a move toward more health-conscious, lower-calorie beverages.

With demand for beer down, smart brewers are on the lookout for fresh revenue streams. If you’ve got tanks sitting empty part of the week, you’re essentially leaving money on the brewery floor.

That’s where contract manufacturing comes in — turning your excess capacity into a profitable business model that strengthens both your bottom line and the broader craft community. At Crafted EPR, we’ve seen countless brewing partners transform their operations through strategic contract manufacturing relationships. Here’s how you can tap into this opportunity.

The Contract Manufacturing Opportunity: What’s Brewing?

Think of contract manufacturing as brewing hospitality — you’re opening your brewhouse doors to brands that have great recipes and marketing chops but lack the equipment to bring their vision to life. You provide the brewing infrastructure, expertise and supplies while they bring the recipes, branding and distribution channels. It’s the perfect marriage of assets that creates value for everyone involved.

This model shines brightest when your fermenters aren’t running at full tilt. Maybe your flagship IPA doesn’t need all your tank space during the winter months, or perhaps your taproom sales follow predictable seasonal patterns. Whatever the case, those quiet periods in your production schedule represent untapped potential. Contract manufacturing transforms downtime into dollars, creating year-round stability for your operation.

The craft beer revolution has created a thirsty market for contract manufacturing services. We’re seeing more brand-focused entrepreneurs who understand marketing and recipe development but aren’t ready to sink millions into building a physical brewery. Your excess capacity could be exactly what these brewing visionaries need to launch their dreams — without either of you overextending financially.

The Financial Fermentation

Let’s talk money — because at the end of the day, your brewery is a business. When you become a contract producer, you’re essentially running your brewing system more days per month, spreading those hefty fixed costs (that monthly equipment lease doesn’t care if you’re brewing or not) across more barrels of production. The math is simple: more brewing days equals better equipment ROI.

Contract manufacturing typically provides the financial stability that seasonal craft breweries dream about. While your summer wheat might fly off shelves June through August, those contract brewing payments keep coming in year-round. Contract manufacturing creates the financial foundation that allows you to experiment with small-batch specialties and seasonal offerings without keeping one eye on the bank account.

When structured thoughtfully, contract manufacturing deals can actually deliver better margins than some of your own distribution channels. Think about it — no marketing costs, no sales team commissions, and none of the logistical headaches of self-distribution. Just straight-up brewing revenue that makes your accountant smile.

Beyond the Balance Sheet Benefits

The advantages of contract manufacturing extend well beyond your P&L statement. Your brewing team gets to flex their creativity and technical skills across a wider range of recipes and styles. We’ve seen head brewers who were getting bored making the same core beers for years suddenly reenergized when tasked with perfecting someone else’s double dry-hopped hazy or barrel-aged stout.

The increased production volume often pushes you past important thresholds with suppliers. Suddenly, you’re ordering enough malt to qualify for that next pricing tier, or buying enough cans to reduce your per-unit packaging costs. These economies of scale improve margins across everything you produce — contract or otherwise.

Perhaps most importantly for brewery culture, contract manufacturing creates stability for your team. Rather than the all-too-common seasonal layoffs that plague our industry, your production staff enjoys consistent hours throughout the year. This workforce continuity helps you attract and retain the kind of talented, passionate brewers who make exceptional beer possible.

Navigating the Contract Manufacturing Regulatory Rapids

Before you brew your first batch under someone else’s label, you’ll need to ensure all your regulatory ducks are in a row. The TTB has specific guidelines for contract brewing that you’ll need to understand inside and out. These federal frameworks establish the ground rules, but don’t forget that state requirements for producing beer under multiple labels vary significantly. What works in Colorado might not fly in California.

Develop a rock-solid contract template that addresses all the critical elements: production specifications, quality standards, intellectual property protection, payment schedules and liability considerations. This isn’t just legal CYA — it’s the blueprint for healthy, drama-free partnerships. We’ve seen too many handshake deals turn sour when expectations weren’t clearly documented from the start.

Also, don’t forget to update your insurance policy to specifically cover contract manufacturing. Your existing coverage probably wasn’t written with contract production in mind, and the last thing you need is an uncovered incident involving someone else’s product.

Honest Operational Assessment

Before you start promoting your contract manufacturing capabilities, take a clear look at what your brewery can realistically handle. Map out your current production schedule and identify capacity gaps. Be brutally honest — if you’re already pulling 12-hour brew days to keep up with your own beers, contract manufacturing might create more headaches than value.

Your quality control systems need to be bulletproof before bringing other brands into the mix. Can you consistently deliver beer that meets exact specifications time after time? Remember, with every batch, your contract production clients put their brand reputation in your hands. Their success depends on your consistency.

Take a walk through your facility and evaluate your storage situation. Where will you store another brand’s specialty hops? Is there space for their branded packaging materials? Can your cold storage accommodate finished kegs and cases awaiting pickup? Physical space limitations often become the unexpected bottleneck in contract manufacturing operations.

Service Menu: From Basic Brewing to Full-Service Partnership

Many brewery contract producers offer flexible service tiers to meet diverse client needs. For some clients, you’ll provide the complete package — sourcing ingredients, brewing to spec, packaging in their materials, and maybe even coordinating distribution. This full-service approach works beautifully for client brands with marketing expertise but limited brewing knowledge.

Other relationships might be more collaborative, with the client providing their unique yeast strain or specialty ingredients while you handle the production process. Contract brewing clients also often require your packaging line because canning equipment is frequently the highest barrier to entry for new brands.

Consider adding value through recipe development services. Your experienced brewing team can help clients dial in recipes for commercial scale or create seasonal offerings that complement their flagship brands. This consultative approach strengthens partnerships and often commands premium pricing.

Pricing: Crafting a Structure That Works for Everyone

Your pricing model needs to balance competitiveness with profitability. Start with a base production fee that covers standard brewing processes and overhead costs. This creates the foundation of your contract manufacturing revenue. Then consider volume incentives — tiered pricing that rewards clients for larger batch sizes while improving your operational efficiency.

When sourcing materials for clients, establish a reasonable markup percentage that reflects the value of your supplier relationships and inventory management. Don’t undervalue these services. It can save clients significant headaches and often provides better pricing than they could secure on their own.

Be transparent about additional costs like production changeovers, cleaning between brands, specialty processes, and storage fees. Clarity in pricing prevents the uncomfortable conversations that arise when unexpected charges appear on invoices.

Set minimum batch sizes that make economic sense for your operation. Your pricing should ensure that even the smallest viable batch generates enough revenue to justify the administrative overhead and production disruption. Remember that changeovers between different brands represent lost productive time. Price accordingly.

Building Your Contract Manufacturing Client Network

The best contract manufacturing clients won’t simply fall into your lap. You’ll need to cultivate these relationships actively. Tap into the incredible networking opportunities at industry events like the Craft Brewers Conference or your state guild gatherings. These settings allow for the kind of face-to-face connections that build trust and open doors.

Distributors can be goldmines for contract manufacturing opportunities. They often know which brands are looking to expand production or enter new markets without building additional facilities. A distributor that already carries your beer and has relationships with brands seeking production can create perfect synergies.

Leverage digital channels by creating a detailed section on your website showcasing your contract production capabilities, equipment specifications and service offerings. Be sure to highlight what makes your facility special — whether that’s your centrifuge for exceptional clarity, your advanced water treatment system, or your high-speed packaging line.

Maintaining Healthy Client Relationships

Once you’ve secured contract manufacturing clients, nurturing those relationships becomes critical to long-term success. Communication is the foundation of every successful partnership. Establish regular check-ins and detailed production reports so clients always know where their beer stands in the process.

Work collaboratively to establish quality standards that satisfy both your brewing principles and their brand expectations. Every contract manufacturing relationship should include clear guidelines for testing, approval processes, and what happens if a batch doesn’t meet specifications.

Be transparent about production timelines and challenges while maintaining the flexibility to accommodate reasonable schedule adjustments. The craft beverage world is unpredictable — sometimes a client’s beer will unexpectedly take off in the market, requiring faster turnaround on the next batch. Your ability to adapt within reason will make you an invaluable partner.

Most importantly, treat your clients’ recipes and business information with absolute confidentiality. In the relatively small craft brewing community, your reputation for trustworthiness will become your most valuable asset.

Running a Tight Contract Production Ship: Operational Excellence

As your contract manufacturing business grows, production scheduling becomes increasingly critical. Group similar beer styles or packaging formats together to minimize changeover time and cleaning cycles. This might mean brewing all your hazy IPAs in sequence, regardless of which client they belong to, then transitioning to lagers.

Coordinate ingredient orders across your production schedule to leverage volume pricing and reduce freight costs. A masterful production calendar balances the needs of your own brands with your contract clients while building in buffer time for the inevitable unexpected issues such as equipment maintenance, delivery delays or quality concerns.

Implement meticulous quality control systems that track each batch from grain to glass. Document standard operating procedures for each client’s products and establish critical quality checkpoints throughout the brewing process. Keep reference samples from every batch for future evaluation if questions arise. Your commitment to quality needs to be unwavering. Remember that your reputation rides on every beer that leaves your facility, regardless of whose label it carries.

Tackling Common Contract Manufacturing Challenges

Every contract production operation faces hurdles — it’s how you handle them that determines your success. Recipe consistency across multiple batches presents one of the biggest challenges. Invest in precise measurement systems and comprehensive batch documentation to ensure repeatability. Client approval of first batches should be mandatory before full production begins.

Scheduling conflicts inevitably arise as your production calendar fills. Develop clear priority protocols and communication systems to manage these situations transparently. Your own core brands might take precedence during peak season, while contract clients get priority during your traditional slow periods.

As your contract production volume grows, capacity limitations will eventually emerge. Be prepared for honest conversations about equipment upgrades or facility expansion to accommodate growth. Many of our brewing customers have funded major capital improvements largely on the strength of their contract manufacturing contracts.

Cash flow timing requires careful management, particularly when fronting the cost of ingredients before receiving payment for the finished product. Structure payment terms to include deposits covering raw material costs, protecting your cash position while offering clients reasonable payment schedules.

Growing Your Contract Production Operation

As contract brewing becomes a more significant part of your business model, consider establishing dedicated fermentation tanks or packaging lines for contracted products. This separation streamlines scheduling and reduces concerns about cross-contamination or recipe confidentiality.

Invest in versatile equipment that can handle diverse beer styles and packaging formats, expanding the range of clients you can serve effectively. A single bright tank that can feed both your canning line and keg filler maximizes flexibility for different client needs.

Cultivate strategic partnerships with ingredient suppliers who can support your expanded production requirements with competitive pricing and reliable delivery. These relationships become increasingly valuable as your brewing volume grows.

Consider training certain team members to specialize in contract production operations, creating internal expertise that improves efficiency and quality. Some larger contract manufacturing businesses even create dedicated roles, like a contract brand manager, to oversee client relationships and ensure seamless production.

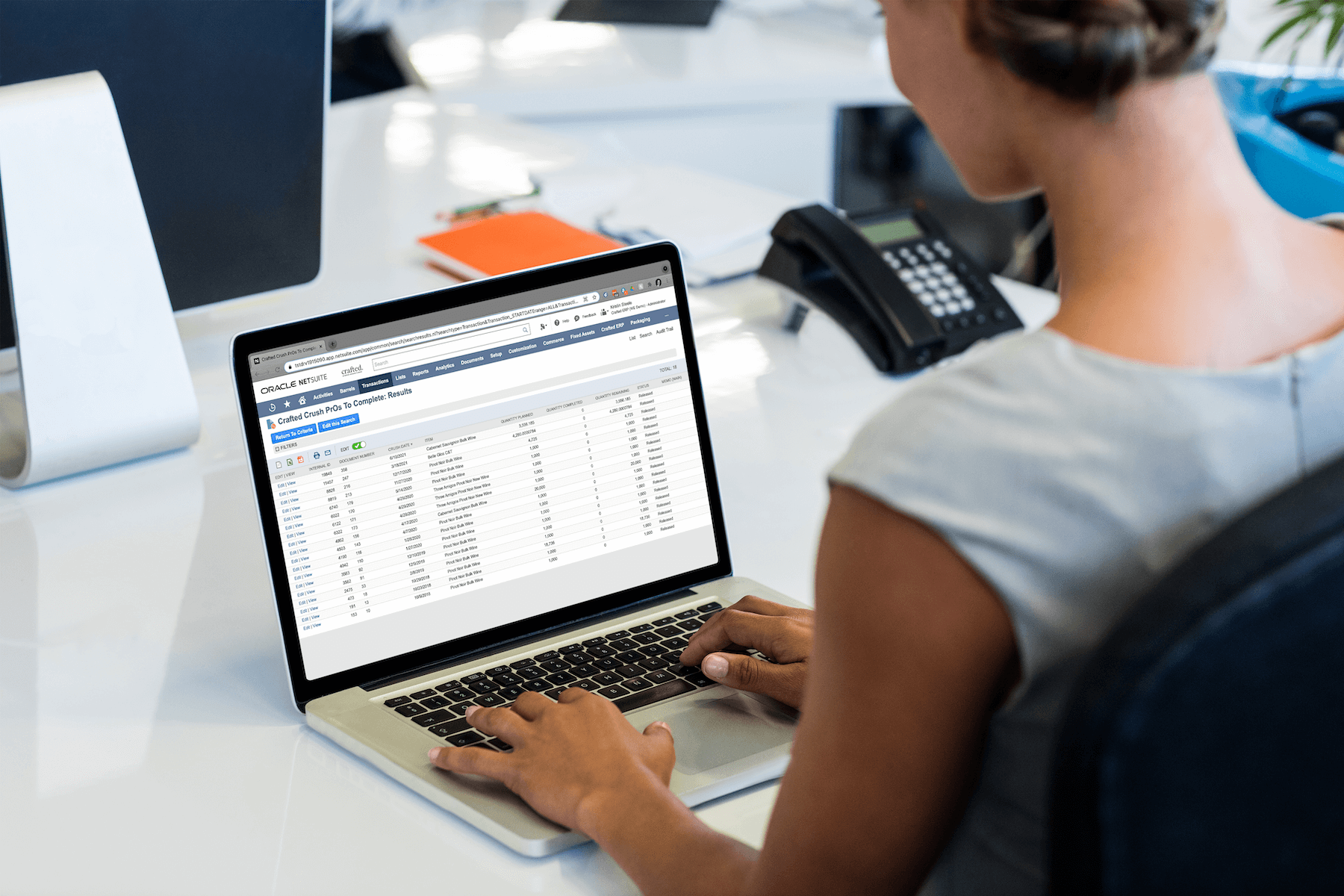

Implement brewery management software specifically designed to handle multiple brands and clients, streamlining administration and improving accuracy across all aspects of production. These systems quickly pay for themselves through reduced errors and improved efficiency.

The Last Pour: Contract Manufacturing as a Strategic Growth Path

At Crafted EPR, we’ve watched numerous brewing partners transform underutilized capacity into thriving contract production operations that create stability, drive growth, and strengthen the broader craft community. This business model allows established breweries to maximize their investments while helping innovative new brands enter the market.

The most successful contract manufacturers maintain a thoughtful balance between their own branded products and contract work. This diversification creates resilience against market fluctuations and provides the stable financial foundation needed for continued innovation and growth.

Whether you’re looking to fill occasional gaps in your production schedule or develop a significant contract brewing business, the key lies in leveraging your existing strengths while building transparent, mutually beneficial relationships. In an industry known for both fierce competition and remarkable collaboration, contract manufacturing represents the best of both worlds — a smart business strategy that helps more great beer reach thirsty consumers.

As you consider your brewery’s future growth paths, remember that those quiet tanks represent opportunity. With careful planning and execution, contract brewing can transform excess capacity from a financial challenge into a profitable business model that benefits everyone involved. That’s a strategy worth raising a glass to.

Whether you’re looking to expand your business model to include contract manufacturing or you’re an experienced contract brewing provider, having the right systems in place to manage your business is critical. Crafted ERP can handle any and all beverage production and business management, allowing you to operate a diverse business in a single software platform. Looking to improve efficiency while expanding your revenue stream? Contact us today.