Barrels don’t lie. They tell the story of your spirit: the conditions in which it’s aged, the attention it received and the precision of your team. However, while the product improves with time, distillery barrel management can quickly spiral into a logistical nightmare if you rely on outdated tools.

Thousands of barrels. Multiple warehouses. Ever-changing compliance rules. One flood, one misplaced barrel or one missing spreadsheet, and the ripple effects hit your bottom line and your brand.

Modern distilleries aren’t just about making great spirits. They’re about managing complexity with confidence. Forward-thinking producers use technology to make distillery barrel management less of a burden and more of a competitive edge.

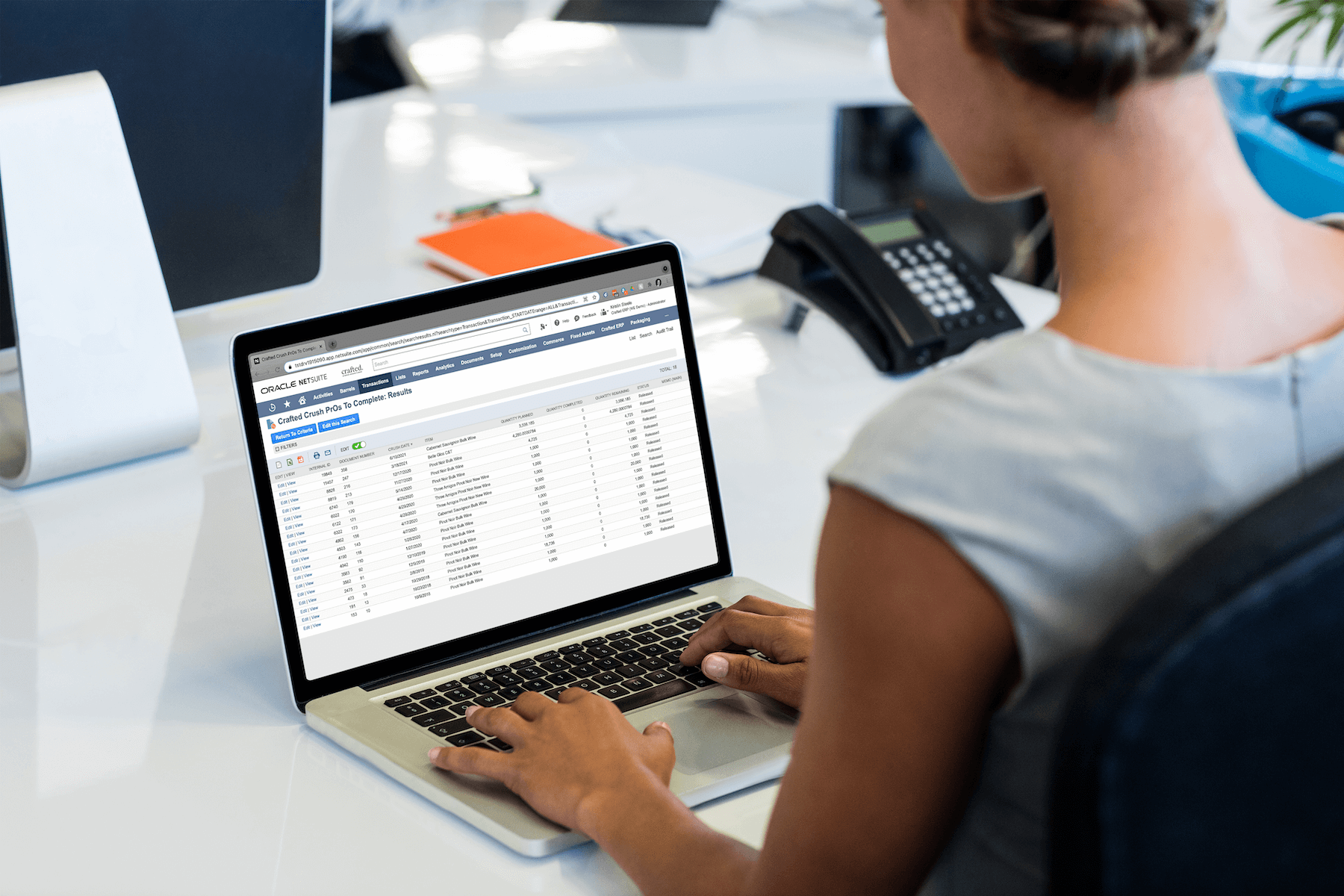

That’s where distillery ERP solutions like Crafted ERP come in — not as generic software, but as purpose-built partners helping you track, trace, plan and protect every drop you’ve worked so hard to age.

Why Barrel Aging Deserves a Starring Role

Barrels are more than vessels — they’re storytellers. The char, the grain, the climate — every variable in barrel aging contributes to the final character of the spirit. Whether you’re aging bourbon, rye, rum or a specialty cask finish, the nuances developed in the barrel are make-or-break for flavor, consistency and ultimately, your brand.

And yet, this critical phase is often managed with spreadsheets or, worse, memory. That’s a bit like tracking fine art with sticky notes.

When you master distillery barrel management, you gain control over inventory value, brand integrity and innovation agility. Especially in the wake of unexpected events, like the 2025 Buffalo Trace flood, having digital oversight isn’t a luxury; it’s your lifeline.

Common Distillery Barrel Management Headaches (and Why They Hurt)

Let’s call it like it is: manual barrel tracking is a time-consuming, error-prone slog. Here’s what distilleries are up against:

- Manual monitoring across warehouses: Got multiple barrel warehouses? Congratulations! You can now juggle Excel spreadsheets, clipboard check-ins and a prayer that nothing falls through the cracks. Tracking maturation conditions across diverse microclimates is essential, but old-school tools can’t keep up.

- Valuation confusion: Your barrels are assets. If one disappears or spoils, that’s not just a bummer — it’s a financial loss. Without real-time data on what’s aging where, valuing that inventory becomes an accounting guessing game.

- Foggy forecasting: How do you plan next year’s releases if you don’t know what’s maturing today? Accurate forecasting requires complete visibility, from fill date to flavor profile.

- Compliance chaos: Ever tried pulling together a TTB report on short notice? If your records are fragmented, you risk penalties or, at the very least, a stressful afternoon.

The Hidden Costs of Manual Distillery Barrel Management

Let’s talk numbers. If even a few barrels go missing or get blended improperly, you’re losing revenue, time and consumer trust. Here’s what’s really at stake:

- Lost or misplaced barrels = lost product: Each barrel might hold thousands of dollars in future sales. Losing one isn’t a blip — it’s a blow.

- Quality inconsistencies: How can you promise consistency across batches if you can’t track exactly what’s in each barrel? Spoiler: you can’t.

- Administrative overload: Your team didn’t get into spirits to become data entry clerks. Manual record-keeping eats up hours that could be spent on innovation and production.

Turning Complexity Into Control

In the words of Jeremy King, CEO of Doozy Solutions, “There’s got to be a better way to do this.” As quoted in American Craft Spirits, he says, “Not only are the accounting complexities tremendous and very difficult, [it becomes more so] when you layer on all the other federal and state and [other] regulations that you have to abide by, [and] long-term and short-term planning. All these different things together were a nightmare for [distillers] just to run their business.”

Crafted ERP is purpose-built to make distillery barrel management smarter and smoother. Here are eight ways distillery barrel management software transforms your operations:

- Production planning with maturation in mind: Know when each barrel hits peak maturity so you can confidently align blending, bottling and release schedules.

- Warehouse mapping and barrel visualization: Navigate your warehouses digitally. Need to locate a specific barrel or group? It’s all on a map — no flashlight or forklift detour required.

- Detailed barrel-level tracking: From char level to fill date, every detail is logged and accessible. This isn’t just traceability — it’s peace of mind.

- Live inventory insights: Want to see how many barrels of 4-year rye are in Warehouse C? One click and it’s there. No guesswork, no lag time.

- Recipe and blend management: Create, test and refine recipes with batch-level control. Keep your core offerings consistent and your innovations sharp.

- Automated cost valuation: No more spreadsheets. Know the dollar value of your aging inventory in real-time, with automatic adjustments for angel share or reclassifications.

- Integrated compliance reporting: Generate TTB reports with a few clicks. Rest easy knowing every data point is documented and audit-ready.

- Mobile-first data capture: Record barrel data on the floor, rackhouse or in the field. Your team has access to the tools they need, where they need them.

Barrel-to-Bottle Traceability

Consumers love a good story. “This came from Barrel #47, aged 6 years in American oak, stored in the north-facing rackhouse.” It’s branding gold.

With Crafted ERP, traceability becomes part of your storytelling strategy:

- Grain-to-glass chain of custody: Know and show every process step. Transparency is trust.

- Barrel history as a marketing tool: Turn distillery barrel management data into content. Highlight unique barrels, share vintage stories, and connect fans to their favorite releases.

- Smart blend integration: Blend with intention, guided by real data on flavor profiles, aging progress and historical success.

- Limited release management: Whether a single barrel pick for a retailer or a holiday special, Crafted ERP makes small-batch tracking scalable and straightforward.

Don’t Let Barrel Management Be a Blind Spot

Barrels hold more than aging spirits; they hold your future product, financial investment and brand’s reputation. A well-run distillery barrel management system lays the foundation for consistency, quality and long-term growth.

The complexity is real: from tracking inventory across warehouses to staying compliant with reporting requirements, the stakes only grow as your operation scales. But so do the opportunities, especially when you have systems in place that give you visibility, traceability and control.

Modern distillery ERP solutions like Crafted ERP aren’t about replacing the craft. They’re about supporting it by giving you modern tools to stay on top of the details, so you can focus on building something that lasts.

Whether you’re growing, diversifying or simply trying to tighten up your barrel program, it’s worth asking: What would more clarity, better data and fewer unknowns do for your team?

We can tell you. Let’s chat!