Scaling a beverage business is thrilling — until you find errors in your spreadsheets, the emails start piling up, and your third facility runs out of kegs.

The truth is, growth in the beverage world doesn’t just mean producing more. It means managing more: more locations, more SKUs, more compliance requirements, more moving parts. And if you’re running the show with disconnected systems or homegrown workarounds, that growth can quickly feel more chaotic than exciting.

Here’s what’s happening across the industry: brands are expanding faster than ever. Producers are acquiring other companies, forming cooperatives or mergers, and moving to multi-site beverage production to meet demand. According to Forbes, M&A activity in the food and beverage space is heating up again, and with it comes a whole new level of operational complexity.

But complexity doesn’t have to mean confusion.

With the right tools, producers can manage multi-site beverage production with clarity, speed and precision, scaling smarter, not just bigger. While challenges abound with multi-site operations, the right beverage production software brings control, consistency and confidence to the entire production network.

Why Multi-Site Beverage Production is Booming

The beverage industry has outgrown the single-facility model. Whether through mergers and acquisitions or the organic expansion of fast-growing brands, companies build their infrastructure to meet rising demand, reduce shipping costs, or serve new markets faster.

You’re not just producing more — you’re producing in more places.

This decentralized growth also mirrors a larger shift toward cloud-first, mobile-enabled operations. As ERP grows and changes, it’s not just about controlling back-office functions — it’s the digital backbone for distributed, fast-moving beverage companies that need to operate in sync from anywhere.

However, while expanding to multi-site beverage production increases capacity, market reach and brand value, it also introduces a complex web of operational challenges.

What Makes Multi-Site Beverage Production So Challenging?

Scaling brings scale-worthy problems. Here are the most significant friction points beverage producers encounter when they go multi-site:

- Complex inventory and supply chain management: Tracking becomes a logistical labyrinth when raw materials, packaging components and finished goods move across multiple facilities. Without centralized visibility, you risk stockouts in one place and overstock in another, not to mention costly reorders and delayed production runs.

- Inconsistent processes and quality standards: Each facility may have its own way of doing things — different standard operating procedures (SOPs), levels of automation and local suppliers. That variability leads to product inconsistencies and quality control headaches that can tarnish your brand.

- Scheduling and capacity utilization gaps: Your central facility may be slammed while a secondary site sits underutilized. Without a unified view of multi-site beverage production schedules and capacity, you’re flying blind, leaving efficiency and profitability on the table.

- Data and communication silos: When each facility uses different tools or manual processes, it’s challenging to share information in real time. Decisions get delayed, teams make assumptions, and leadership has to dig through ten systems to get a clear picture.

- Resource allocation inefficiencies: Duplicate software licenses, disjointed procurement processes and redundant admin work consume time and money. Without standardization, you’re paying too much for too little insight.

- Compliance and traceability risks: Regulatory requirements vary state by state. Without a centralized system, managing lot tracking, labeling laws and reporting across state or country lines can lead to compliance gaps.

- Increased admin overhead: More sites often mean more systems, spreadsheets, duplicate data entry and opportunities for errors.

How Crafted ERP BevX Brings Order to Multi-Site Beverage Production Chaos

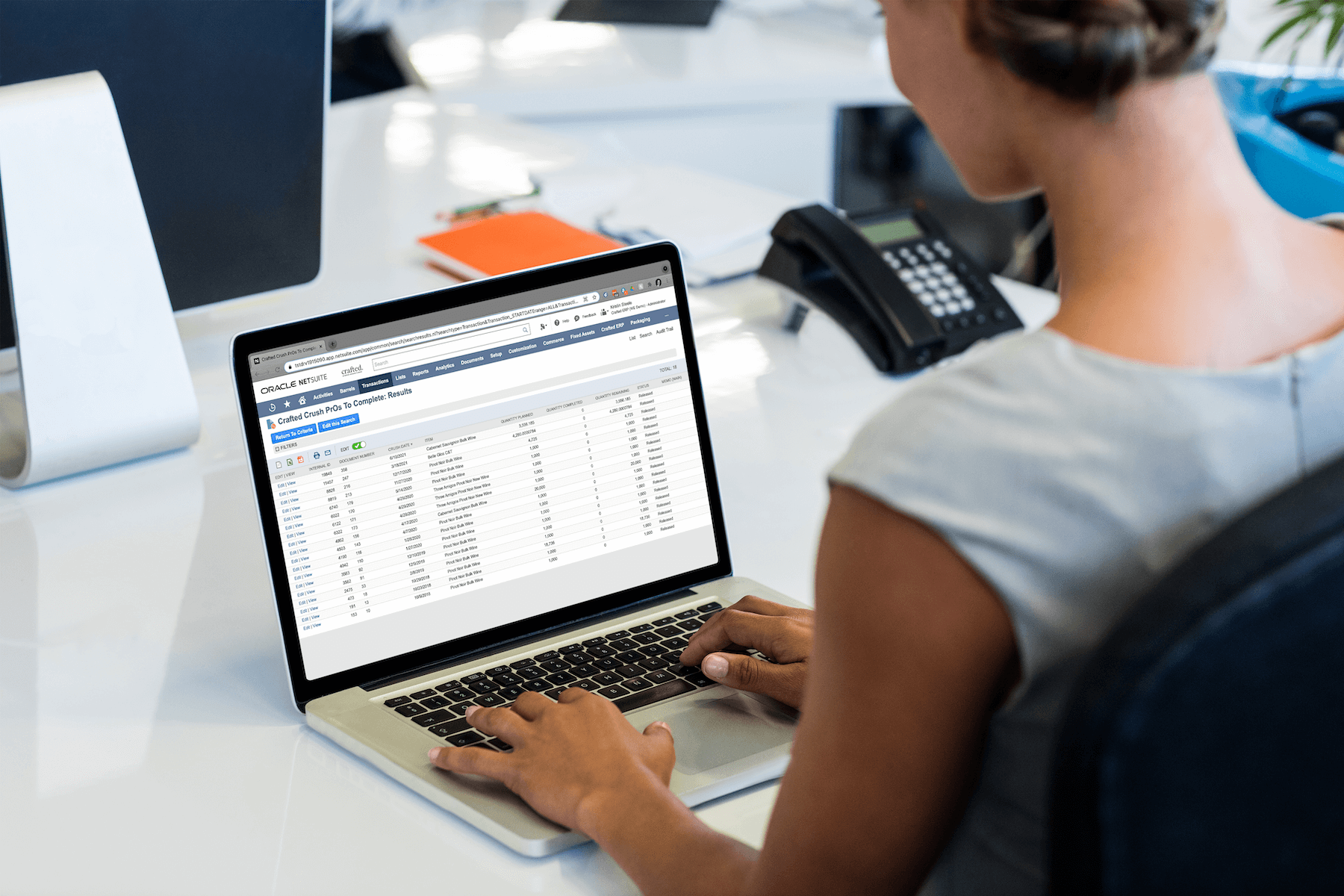

Crafted ERP BevX was purpose-built for beverage producers, and it’s designed to shine when complexity ramps up. Here’s how it gives you the control you need.

Cloud-based and always-on

BevX is entirely cloud-based, allowing every team member, from production managers to the finance team, to access the system anytime, anywhere. No more calling someone at the other facility to check tank status or inventory.

This reflects one of the biggest ERP trends of 2025: cloud adoption for greater agility, lower IT overhead and seamless scalability. Cloud ERP also supports edge computing, allowing data to be processed closer to the source, critical for multi-site producers managing real-time inputs from IoT-connected equipment, sensors or mobile users on the floor.

Real-time visibility across locations

BevX unifies your entire operation. Whether it’s anticipating supply delays, identifying cost variances, or flagging efficiency gaps, smart insights are always a click away. You’ll get a clear (and customizable) dashboard showing production status, inventory levels, sales performance and more across all your facilities. No more siloed data. No more guessing.

Multi-site beverage production planning

BevX lets you schedule production runs across multiple locations with total transparency and control. Need to shift packaging to a facility with more line time? Easy. Want one site to focus on spirits while another handles functional beverages? Done.

Two-tier ERP — another emerging strategy — also plays a role in this context. Larger producers may want to maintain a central ERP system for financials while rolling out BevX as a nimble, cloud-based Tier 2 solution across their expanding facilities. This approach reduces cost and complexity while supporting rapid expansion.

Centralized procurement, accounting and compliance

With a single system for purchasing, accounting and compliance, you can centralize purchasing power, ensure accurate reporting, and maintain control without the need for duplicate staff or systems.

Built for beverage diversity

Whether you’re making classic spirits, crafty brews, canned cocktails or functional tonics, BevX adapts. You can build custom workflows for each product type or site and manage everything from a single platform.

Smart transfer orders and intercompany transactions

Need to send raw materials from your East Coast site to your new facility out west? BevX makes transfers clean, traceable and accurate. It also handles the financials, so your books stay accurate and auditable.

Best Practices for Rolling Out ERP Across Multiple Sites

Want to avoid headaches during implementation? Follow these field-tested best practices:

- Standardize what matters: Use BevX to create consistent workflows for multi-site beverage production, QA, inventory and finance. However, stay flexible where it counts — such as packaging formats, scheduling preferences or co-packer integrations.

- Phase your rollout: Rolling out ERP across all sites simultaneously might work for smaller teams. But for most, a phased approach (site by site) allows you to learn, adapt and build internal champions.

- Train the right way: Tailor training to each role — production staff need different workflows than accounting, and compliance teams have different needs than operations managers. Use hands-on sessions, documentation and local superusers to boost adoption.

- Plan for change management: ERP changes how people work, not just what they use. Communicate early, listen to feedback, and celebrate early wins to maintain high morale and strong adoption.

As mobile ERP capabilities improve, it’s also wise to ensure your rollout supports on-the-go access. Today’s workforce expects to view workflows, log production data, and approve POs from mobile apps — and that convenience drives adoption.

Bi-Coastal and in Control: Athletic Brewing’s Success with Multi-Site ERP

Athletic Brewing Co., the leader in non-alcoholic craft beer, grew fast, boasting award-winning production facilities on both coasts. But with growth came complexity. Disconnected systems, manual processes and siloed data made it harder to scale efficiently.

“When I came on board, there was a disconnect between inventory and production,” explained Rob Riccio, enterprise application manager at Athletic. “It was difficult to keep track of everything.”

That all changed when they implemented Crafted ERP.

By switching to a unified platform, Athletic Brewing transformed its multi-facility operations. Manual workflows were automated, and month-end close times dropped by 10–15%. Teams gained granular visibility into production costs, and batch management became more precise across both locations.

With real-time data, streamlined scheduling and integrated reporting, Athletic now runs smarter. With Crafted ERP as its operational foundation, Athletic is positioned for continued growth in 2025 as a category-defining brand in the booming NA beer space.

Multi-Site Beverage Production Doesn’t Have to Mean Compromising Control

Managing multiple production sites is no small feat. Whether you’re crafting spirits, canning functional beverages, or producing non-alcoholic beer across regions, complexity comes with the territory. But complexity doesn’t have to slow you down — or weigh down your team with redundant systems and reactive decisions.

With the proper foundation, scaling becomes a strategic approach. Crafted ERP BevX provides beverage producers with a single source of truth, tighter control over costs, and the flexibility to adapt to whatever comes next — new facilities, new markets or new categories.

Operational excellence at scale is repeatable. And with the right tools, it’s yours to own. Let’s talk about leveling up!