Managing a winery operation involves far more than cultivating grapes and mastering the art of fermentation. One crucial yet often overlooked aspect is winery inventory management. This involves tracking everything from raw materials used in the wine production process to finished case goods.

Effective winery inventory management ensures that organizations maintain optimal stock levels, often resulting in reduced production costs and enhanced customer satisfaction. On the other hand, poor inventory management can lead to significant mistakes and lost revenue.

Using the right winery software, companies can make stock management easier. It allows winery businesses to save time, cut costs and improve accuracy.

5 Ways Software Enhances Wine Inventory Management:

1. Streamlined Inventory Tracking

Managing a diverse inventory of wines, varietals, vintages and packaging materials becomes challenging when spread across various storage locations and sales platforms. Winery software centralizes this process. It creates a real-time digital inventory database, logging and categorizing each item. This clarity helps you see what’s available, where it is and when to restock. Winery software can generate detailed reports for each inventory item. It tracks lot numbers, barrel locations, vineyard origin and aging stages, all of which are key to an efficient operation.

2. Accurate Inventory Forecasting

Forecasting stock needs accurately is crucial to successful winery inventory management. Winemakers need tools to predict demand, trends and supply needs. Mistakes can lead to excess production, wasted resources or stockouts.

Winery software uses historical data and predictive analytics for precise forecasting. Comprehensive data helps ensure you order the right quantities and maintain optimal production.

Inaccurate inventory forecasting can harm a winemaking business, where production is complex and time-sensitive. Some of the downsides include:

- Overstocking: Excess inventory, particularly perishable goods, can lead to increased holding costs and potential waste. Money is left tied up in excess inventory, which can result in cash flow issues.

- Understocking: Not having the right materials on hand when needed can lead to missed sales and unhappy customers. A brand’s reputation can be damaged if products are not available when needed.

- Increased operational costs: Inaccurate forecasting can cause a ripple effect throughout the supply chain, leading to problems and increased costs. For instance, rush orders for understocked items may incur higher purchase and shipping costs.

- Impaired production planning: Inaccurate winery forecasting can significantly disrupt production schedules. Insufficient supplies, like grapes, may halt production and lead to wasted time and resources.

- Poor customer service: If a winery often runs out of stock due to bad forecasting, it may not meet customer demand. This can lead to losing customers to competitors.

- Strained supplier relationships: Wineries that have to constantly adjust orders may frustrate vendors and damage the relationship. ERP software improves winery forecasting accuracy and enhances operations.

3. Enhanced Case Goods Management

Managing inventory across sales channels, wine clubs, retail and direct-to-consumer sales requires strategic planning.

Winery software provides visibility into case goods across channels, showing what sells best where. It enables better inventory allocation and reduces stockouts and logistical challenges.

4. Simplified Compliance Reporting

Wineries face strict regulatory requirements and must provide detailed reports of on-premise operations. Agencies like the U.S. Alcohol and Tobacco Tax and Trade Bureau (TTB) require these reports.

Winery management software can automate much of this process. By diligently tracking inventory, production and sales data, the software can generate accurate winery compliance reports quickly and efficiently. This saves considerable time and reduces the risk of errors that can lead to regulatory penalties.

5. Integrations with Other Business Systems

A comprehensive winery software platform unifies business processes with real-time inventory data syncing, accurate financial reports and efficient order management.

Winery ERP solutions enhance inventory management, boost efficiency, reduce costs and improve decision-making. Beyond monitoring inventory, it helps you understand your business more thoroughly and better satisfy customer needs.

Next Steps for Implementing an Inventory Management System

No one can deny the crucial role that effective inventory management plays in the success of any winery operation. Leveraging the power of winery ERP software as your inventory management solution can bring about substantial improvements across your organization.

Real-time visibility into inventory levels and accurate forecasting help streamline order management, control costs and improve customer satisfaction. While there are many inventory software options on the market, it’s important to choose one that fits the specific needs of the wine industry.

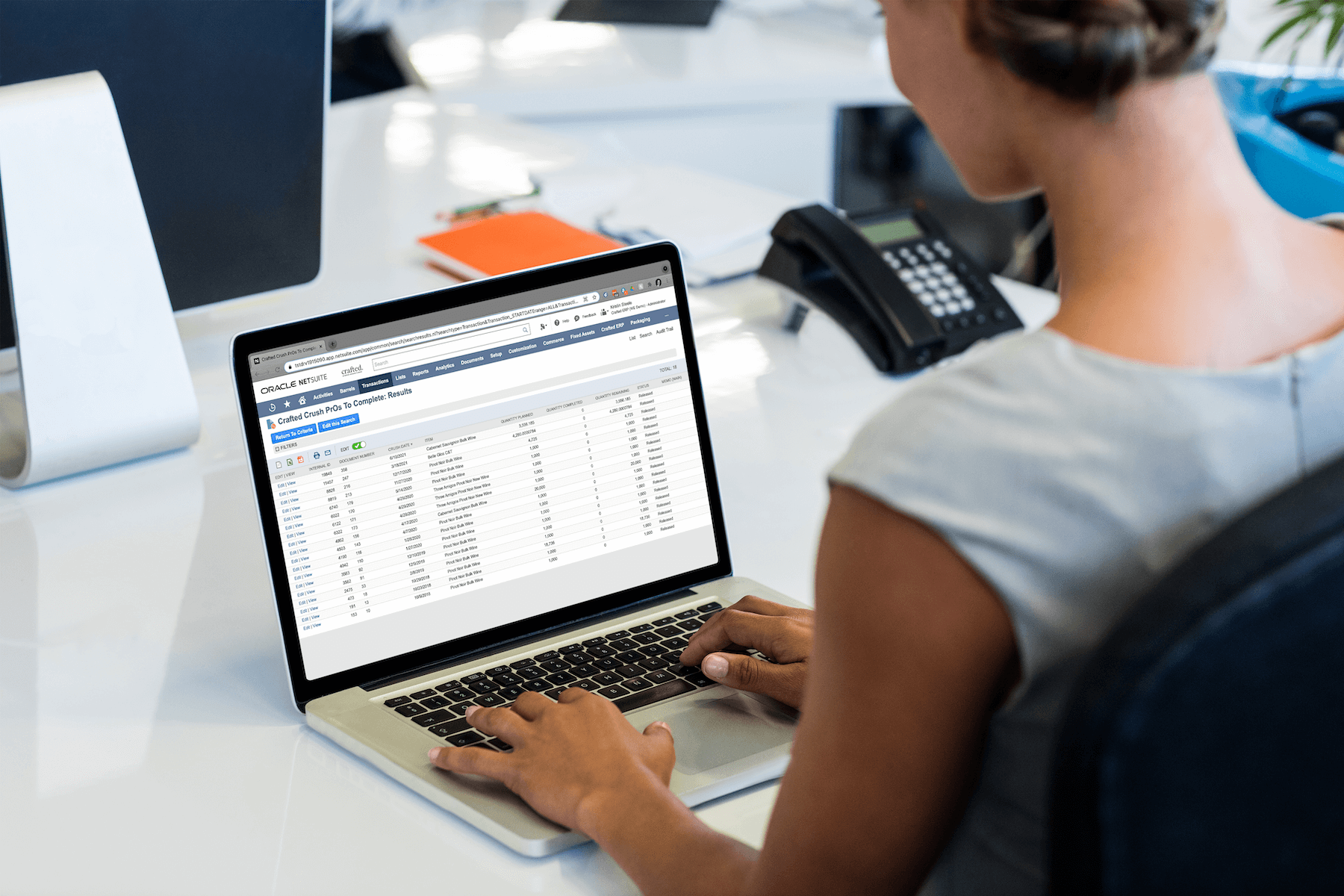

Crafted ERP Winery Software is developed by former head winemakers and wine industry professionals. It includes features specific to winemaking, bottling, inventory management and demand planning. The cloud-based solution also supports winery compliance, accounting, data analysis and sales.

If you struggle to maintain accurate inventory counts across disparate systems, contact our U.S. and Australia teams now. We can discuss your needs and share more about our industry-leading winery management software.