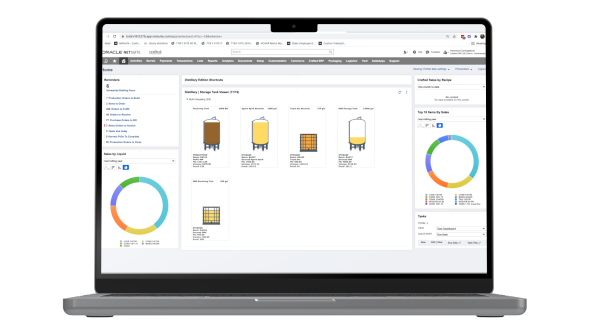

Standardize and optimize production line schedules, track each batch, keg, and barrel at every stage, and digitize batch logs and tank readings. It sounds like an impossible ask, but it’s not. It’s Crafted ERP, the leader in batch manufacturing and post-production operations for the beverage industry.

Whether you’re making beer, wine, spirits, RTDs – you name it – or using kegs, barrels, cans, bottles, customized plastic packaging (looking at you, Buzzballz!), or any other container, you’ll have it all in hand and under control.